Howden Compressor collaborated with the Swedish company now known as SRM is the 1930’s to design and manufacture the world’s first operational

screw compressor.

Howden Compressor further developed this concept in the 1960’s to introduce oil injected twin screw compressors to the market pioneering the use of

this technology, which now dominates gas compression and refrigeration applications worldwide.

With over 50 years of design and manufacturing experience, Howden Compressors are able to provide optimised product which is capable of operation

on all known refrigerants and vast array of Hydrocarbon gases. |

|

|

|

| HOWDEN COMPRESSOR CONSTRUCTION |

|

|

Howden twin screw compressors have paired rotors, machined from solid bar or forgings which involves a high degree of complexity and

accuracy.

Normally casings will be cast iron, machined to close tolerance levels. However, to match particular gas requirements, high discharge pressure

applications, or applicable international standards and codes, alternative casing construction in spheroidal graphite iron or various grades of

steel

will be offered when appropriate.

Alternative designs of compressors from the Howden product range are available as required. Some typical examples of alternatives are given

below. |

|

| ㆍTwin Wall Construction with Sleeve Bearings |

|

| ㆍSuperfeed |

|

| ㆍSingle Wall Construction with Roller Bearings |

|

| ㆍOil cooling |

|

| ㆍSlide Valve Capacity Control from 100-10 percent |

|

| ㆍLiquid Refrigeration Injection |

|

| ㆍInverter Speed Control |

|

| ㆍSpecialist Sealing Systems |

|

| ㆍVariable Volume Ratio |

|

|

|

|

|

FEATURES AND BENEFITS |

|

|

| Positive Displacement |

Cannot surge. High compression ratios per stage. |

| Rotary Action |

Vibration free running.

Extreme reliability & on-line availability.

Smooth gas flow, low pulsation.

Lightweight foundations. |

| Lightweight foundations. |

Ability to withstand high pressure differences. |

| No Inlet or Outlet Valves |

Lower maintenance costs |

| Compact Size & Light Weight |

Minimal space and foundation requirement, resulting in low installation costs. |

| Designed for Long Periods of Continuous Running |

Maximum on-line availability

Minimal service requirements |

|

|

|

|

|

|

| HOWDEN COMPRESSOR CONSTRUCTION |

|

|

|

|

Howden oil injected twin screw compressors are used for liquid chilling, direct refrigeration, and for

hydrocarbon gas applications involving hydrocarbons, fuel gas, or other specialist applications.

In some instances, hydrocarbon gases such as propane, butane or propylene, will be used as an

industrial refrigerant. |

|

|

|

|

UNIQUE FEATURES AND BENEFITS OF OIL INJECTED |

|

|

| Slide Valve Capacity Control |

Capacity and energy absorbed match system demand. |

| Variable Volume Ratio |

Maximises energy efficiency |

| Liquid Refrigerant Injection |

Reduces capital cost with minimal reduction in operating efficiency. |

|

|

|

TYPICAL APPLICATIONS / GAS HANDLING |

|

|

| TYPICAL APPLICATIONS |

Industrial Refrigeration , Hydrocarbon Processing, Fuel Gas Compression

Gas Liquefaction, Liquid Chillers , Petrochemical and Chemical Processing

Food Processing, Marine Air Conditioning & Refrigeration, Natural Gas Gathering

Carbon Dioxide Recovery, Breweries ,Coke Oven Gas, Mine Cooling |

| Refrigerants |

NH3, R12/R134a, R22/KLEA 66/AZ5000, R22/KLEA 66/AZ5000/AZ 50, Propane, Butane,Propylene |

| Gases |

Ammonia, Methane , Butane, Natural Gas, Coke Oven Gas, Nitrogen, Fuel Gas, Propan,

Helium, Propylene, Hydrocarbon (Wet & Mixed), Sour Gas, Town Gas, Hydrogen |

|

|

|

|

|

|

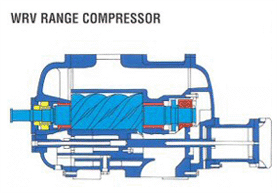

| WRV COMPRESSORS |

|

|

|

|

WRV compressors represent the “bench mark” against which industry comparison is made for both gas

and refrigeration applications. |

|

|

|

|

Features and Benefits of WRV Compressor |

|

|

| Plain-Shell Type Journal Bearings |

Long operational life span |

| Double Wall Construction |

Suitable for high pressure application |

| Optional Material of Construction |

Flexibility to match project specification(e.g. API 619) |

| Oil Injected Seal Bearing Construction |

High quality gas seal from simple construction |

| Range of Capability |

Probably the most comprehensive range of capacity available |

| Installed Compressors |

More than 20,000 WRV compressors installed worldwide |

|

|

|

|

|

|

|

All WRV range compressors are of double wall

construction and utilise white metal, sleeve type journal

bearings with pressurised shaft seal.

A full range of Vi options from 2.1 to 5.8 is offered for

each compressor while slide valve capacity control is a

standard feature on all compressors. |

|

|

|

|

|

|

|

| XRV COMPRESSORS |

|

|

|

|

XRV compressors have been developed specially for the refrigeration market. |

|

|

|

|

Features and benefits of XRV compressors include |

|

|

| Ease of Installation |

Ideal for horizontal separator applications |

| Use of Roller Bearings |

No oil pump for over 90% of installations |

| Variable Vi |

Available with either adjustable or fully automatic Vi system |

| Stepless Capacity Control |

Combined with variable Vi, gives maximum energy saving |

| Ease of Service |

Separate end covers give easy access to rolling elements |

|